-

MENSWEAR

-

Questions?

Schedule Appointment Schedule Virtual Consultation

Talk to us on our Live Chat or call us at 1-855-979-SUIT(7848)

-

-

WOMENSWEAR

-

Questions?

Schedule Appointment Schedule Virtual Consultation

Talk to us on our Live Chat or call us at 1-855-979-SUIT(7848)

-

-

DESIGN

-

Questions?

Schedule Appointment Schedule Virtual Consultation

Talk to us on our Live Chat or call us at 1-855-979-SUIT(7848)

-

-

SHOWROOMS

-

Questions?

Schedule Appointment Schedule Virtual Consultation

Talk to us on our Live Chat or call us at 1-855-979-SUIT(7848)

-

- Book Appointment

Toggle Nav

Search

Skip to Content

- FAST DELIVERY

- CUSTOM MADE

- PREMIUM FABRICS

-

MENSWEAR

-

![Suitablee header menu image]()

Questions?

Schedule Appointment Schedule Virtual Consultation

Talk to us on our Live Chat or call us at 1-855-979-SUIT(7848)

-

-

WOMENSWEAR

-

![Suitablee header menu image]()

Questions?

Schedule Appointment Schedule Virtual Consultation

Talk to us on our Live Chat or call us at 1-855-979-SUIT(7848)

-

-

DESIGN

-

![Suitablee header menu image]()

Questions?

Schedule Appointment Schedule Virtual Consultation

Talk to us on our Live Chat or call us at 1-855-979-SUIT(7848)

-

-

ACCESSORIES

-

SHOWROOMS

-

![Suitablee header menu image]()

Questions?

Schedule Appointment Schedule Virtual Consultation

Talk to us on our Live Chat or call us at 1-855-979-SUIT(7848)

-

- Book Appointment

- Pricing

- WEDDINGS

- BUSINESS

- GIFT CARDS

OUR FIT GUARANTEE!

YOUR FIRST PURCHASE? NO WORRIES!

The majority of our customers find their initial purchase to be a perfect fit. Our advanced algorithms and Artificial Intelligence, refined by thousands of diverse body types in our database, ensure a tailored fit with a 95% success rate. Whether you opt for self-measurement or use our Automatic Sizing Technology, rest assured of a near-perfect fit.

OUR FIT GUARANTEE POLICY ENSURES A HASSLE-FREE PURCHASE:

- 1. Need alterations? Simply visit your local tailor, snap a picture of the receipt, and send it to us. We'll provide a store credit or refund (up to $100 per suit).

- 2. Collaborate with our team. If alterations aren't feasible, SUITABLEE will remake your first order to meet your sizing specifications.

-

MENSWEAR

-

Questions?

Schedule Appointment Schedule Virtual Consultation

Talk to us on our Live Chat or call us at 1-855-979-SUIT(7848)

-

-

WOMENSWEAR

-

Questions?

Schedule Appointment Schedule Virtual Consultation

Talk to us on our Live Chat or call us at 1-855-979-SUIT(7848)

-

-

DESIGN

-

Questions?

Schedule Appointment Schedule Virtual Consultation

Talk to us on our Live Chat or call us at 1-855-979-SUIT(7848)

-

-

SHOWROOMS

-

Questions?

Schedule Appointment Schedule Virtual Consultation

Talk to us on our Live Chat or call us at 1-855-979-SUIT(7848)

-

- Book Appointment

- Home

- The SUITABLEE Perspective

- Fits & Fabrics

- What Makes a Quality Suit

What Makes a Quality Suit | Custom Suits Made Easy.

English

English

Français

When you step into a room, your suit speaks before you do. But what sets a remarkable suit apart from an average one? At SUITABLEE, we know that true quality is more than skin deep, it's found in the fabric, construction, fit, and detailing that combine to create a suit designed to move, breathe, and last.

This guide takes you behind the seams, revealing the components that define a premium suit and how each element contributes to both comfort and confidence.

The Fabric: The Foundation of Every Great Suit

The material used in a suit significantly influences its appearance, comfort, durability, and value. While there are many fabric types available, the highest‑quality suits are typically crafted from natural fibers, especially wool.

Why Wool Is the Gold Standard

- Breathability & Climate Versatility: Wool suits naturally regulate temperature, keeping you cool in warm weather and comfortably warm when it’s cold.

- Durability & Shape Retention: Wool has “memory”—it resists wrinkles and retains structure even after multiple wears.

- Natural, Luxe Feel: 100% wool or virgin wool (never processed or recycled) offers a softer, more refined hand‑feel and drape.

Although wool is most common, other natural fabrics like cashmere, silk blends, linen, and cotton can be excellent for specific climates or occasions. Some luxurious suits even incorporate rare fibers like vicuña or cashmere for enhanced softness, though these can reduce durability if overused.

Understanding Super Numbers

When selecting wool, you’ll often see a label like Super 100s, Super 120s, Super 150s, etc. These Super numbers relate to the fineness of the wool fiber, measured in microns and affect softness, feel, and performance.

- Lower Super numbers (Super 100s–120s): Durable and versatile, ideal for everyday business suits.

- Mid range (Super 130s–150s): A balance of softness and durability, great for dressier or frequently worn suits.

- High range (Super 160s+): Ultra‑fine and luxurious, best for special occasions but less robust for daily use.

Higher Super numbers don’t automatically mean “better”, finer fibers can be more fragile, so choosing the right Super level depends on how and how often you’ll wear the suit.

Explore our Fabric Collection during the Customization Process and see how each fabric elevates the silhouette of your custom suit.

This video provides a visual guide to the same material, helping you see how fabric choice affects drape, comfort, and overall quality:

The Construction: Built for Performance and Longevity

While fabric sets the tone, construction is what determines how a suit performs, fits, and ages. A well‑constructed suit moves naturally with your body, maintains its shape, and lasts longer.

Canvas Interfacing: Full Canvas vs. Half Canvas

The internal canvas is a hidden structural layer sewn between the outer fabric and the lining. The way this canvas is made shapes how the jacket drapes and wears over time.

- Full Canvas: A continuous canvas from shoulder to hem. Offers superior drape and longevity and molds to your body over time.

- Half Canvas: Canvas from shoulder to mid‑chest, with the lower front typically fused. A more affordable option that still offers good structure where it counts.

- Fused (Glued): Least expensive but prone to bubbling and rigidity when the glue breaks down.

Hand‑stitched canvassing, especially in bespoke tailoring, will produce a softer, more natural drape and better long‑term shape. At SUITABLEE, every suit is crafted with canvassing material made from wool and horsehair or camel hair. It's stitched, not fused, for breathable, lasting performance.

Lapels, Padding, and Pad Stitching

The jacket’s shape is enhanced by careful lapel and collar construction:

- Pad stitching around the lapels and collar allows the cloth to sit properly without flopping or stiffening.

- Quality padding and stitching give the lapels a smooth, elegant roll rather than a hollow or collapsed appearance.

When assessing a jacket, look for subtle shaping and natural body movement rather than rigidity.

Watch this video for a visual walkthrough of quality suit construction, from the internal structure to the finishing details that define a refined jacket:

Suit Pants: Small Details, Big Impact

A quality suit doesn’t stop at the jacket. Well-made trousers complete the experience.

Telltale Signs of Superior Pants Construction

- Inner Front Lining: Adds comfort and structure to the thigh area, especially important in formal trousers.

- Fly Design: Clean finishing with concealed stitching and a fabric guard under the zipper ensures durability and comfort.

- Curtain Waistband Pleats: Found in tailored pants, this feature hides inlays and improves flexibility at the waistband.

- Adjustable Side Tabs: An alternative to belt loops for a sleeker, cleaner silhouette. These tabs are seamlessly built into the waistband, using the same suiting fabric and secured with buttons or buckles.

Well‑constructed trousers aren’t just about aesthetics, they contribute to mobility and comfort throughout the day.

The look: Baby Blue Three-Piece Suit with Azure Stripe Dress Shirt

Details That Distinguish True Quality

Pattern Matching

In premium suits, patterns like pinstripes or checks are precisely aligned at seams across lapels, sleeves, and trousers. This ensures visual flow and harmony.

Functional Buttonholes and Boutonniere Stitching

True quality shows in the function:

- Working Sleeve Buttons (Surgeon’s Cuffs): Signal craftsmanship.

- Functional Boutonniere Hole: Paired with a small interior thread loop to hold flower stems properly. This is a detail overlooked in mass-produced suits.

Visible Hand Stitching

Discreet hand-sewn stitches along the lapels, pockets, or sleeves are signs of a tailor’s touch. Personalized care that sets your suit apart from machine-made alternatives.

Watch this video for a close-up look at the finishing details that define a premium suit:

Suit Customization Options That Matter

Today’s best suits offer extensive customization, allowing buyers to match their personal style without compromise.

Popular elements you can personalize include:

- Fabric selection, from classic wool to seasonal blends

- Lapels, such as notch, peak, or shawl styles

- Lining color and pattern

- Pocket styles and placement

- Buttons, stitching, monograms, and vents

Unlike typical off-the-rack suits, SUITABLEE’s Suit Design Platform gives customers the freedom to personalize nearly every aspect of their suit. The result is clothing that feels truly personal and distinctive, delivered efficiently and without the long wait times or high costs traditionally associated with custom tailoring.

Ready to personalize every detail? Design Your Suit →

Once the design details are chosen, fit is what determines how that customization looks on the body.

Fit & Measurements: The Final Mark of Excellence

All of the above factors only shine when the suit fits well. Even premium fabric and expert construction will fall flat if the jacket pulls, the shoulders collapse, or the proportions feel off. Fit is what turns craftsmanship into confidence.

Modern tailoring increasingly relies on digital patterning, measurement models, and data-driven sizing to reduce guesswork. SUITABLEE uses AI-assisted sizing to improve accuracy for online ordering and repeat purchases. Our Automatic Sizing Technology is trained on thousands of real body scans and converts your inputs from a 12-question survey into a personalized digital pattern. That pattern is then refined over time using customer feedback, helping deliver a more consistent fit with fewer adjustments.

Key Fit Zones Explained

- Shoulders: Should lie flat and clean with no divots or overhang

- Chest: Should allow movement without pulling across the front

- Waist: Should taper neatly without strain or excess fabric

- Sleeve and pant length: Should be balanced to your proportions and lifestyle

A quality suit should follow your natural lines without pulling or gaping, allow freedom of movement, sit cleanly at shoulders, chest, and waist, and maintain balance when buttoned.

Customize this Cinnamon Double Breasted Wool Suit to your own version →

How to Spot a Quality Suit in 60 Seconds

Use these quick checks when shopping in-store or evaluating a suit you already own.

- Check the fabric label

Look for 100% wool or high wool content, especially merino for versatility. - Do the pinch test for canvas

Pinch the jacket fabric near the chest. If you can feel a third layer floating between fabric and lining, it may be canvassed. - Look at the lapels

Quality jackets show a natural roll. Cheaper jackets often look flat or overly stiff. - Inspect buttonholes and finishing

Look for clean stitching, tidy edges, and functional details where expected. - Check pattern alignment

On stripes or checks, patterns should meet cleanly across seams, pockets, and lapels.

These small signals reveal a lot about how the suit was made.

Care and Longevity: Keeping Your Suit at Its Best

A quality suit can last many years with the right care:

- Use wide wooden hangers and breathable garment bags for storage

- Steam out wrinkles between dry cleans to preserve natural fibers

- Rotate suits to prevent overuse and allow recovery

- When traveling, use a garment bag or fold garments carefully to protect structure

Proper care enhances performance and appearance over time.

The SUITABLEE Perspective

At SUITABLEE, we define a truly great suit as more than fabric and fit. It is the product of modern engineering, data-driven precision, and meticulous craftsmanship working in harmony.

Each garment is developed through AI-powered insights, digital pattern creation, and advanced production methods to achieve a fit that feels personal, looks refined, and remains accessible without the cost typically associated with traditional custom tailoring. Whether you visit one of our showrooms in Old Port Montreal, Quartier Dix30 in Brossard, or downtown Ottawa, or choose to design your suit online, the experience is built to be efficient, reliable, and centered around you.

No guesswork. No waste. Just smarter suits made better.

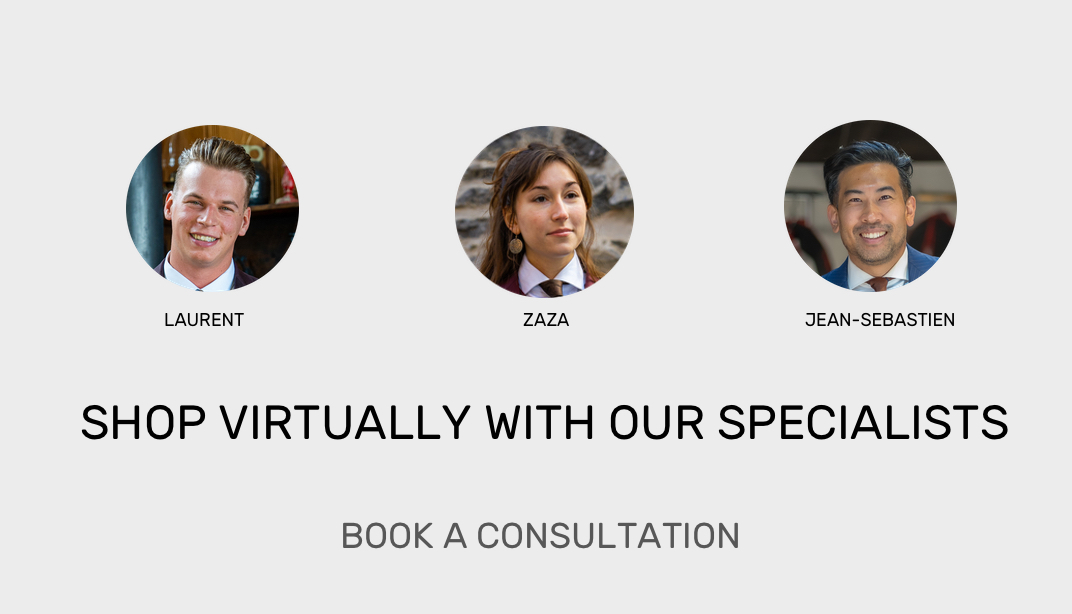

Book an Appointment and let a dedicated specialist guide you through fit, fabric, and design for a quality suit made to your measurements.

Share on Facebook

Share on X

Share on Pinterest

Comment(s)

Available in:

English (US)

(Current)

Available in:

English (US)

(Current)

Categories

- Fits & Fabrics (6)

- Style Guides (6)

- Wedding Style (6)

- Trends & Inspiration (4)

Recent Posts